Process Automation

Customized marking machines that can be integrated with hard automation and robots.

ABOUT US

30 years of trustworthy identification

Connect with an identification expert

Identification that survives

Extreme

Temperatures

Harsh

Chemicals

Medical

Research

UV

Exposure

InfoSight News

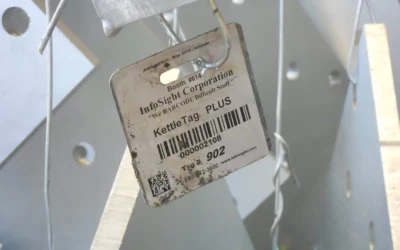

Introducing KettleTag®PLUS EZ – A Quicker, Easier Identification Tag for Galvanized Steel

KettleTag®PLUS EZ is an innovative solution for barcoded identification of galvanized steel – NO laminator required.

Choosing a Barcode to Track In-Process Pipe and Tube Products

Simple solutions are often favorable, especially in complex situations. Just ask the busy barista how they feel about making an upside-down caramel macchiato versus serving up a black coffee. Sure, the macchiato may be more fun to drink, but it’s going to slow them down and there are more opportunities for mistakes. The black coffee makes their customer happy sooner, with little room for error.

InfoSight Connects with Customers at The Precast Show

Speaking about his recent experience at The Precast Show in Kansas City, MO, Connor Sampson, an InfoSight Sales Specialist, says “They seem to do an excellent job of keeping attendees engaged and active. The show floor always seems to be crawling with people.”

Join the InfoSight Team

Operation Manager

When new projects are uneventful, that’s when you know they are working well and that is how this project with InfoSight is going.

Central Texas Iron Works Manager

InfoSight barcoded tags are a tool that allows us to keep up with the faster moving manufacturing process. This tool is important to the whole process.